|

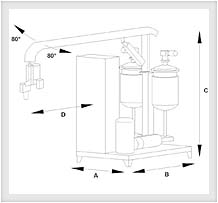

CMC 2TJ

The modern technologies employed for molding polyurethane foams and the ever increasing need to operate efficiently and containing operating costs have reduced the use of low-pressure technology. Special applications, such as low-flow casting, small production volumes and mixing of specific products, make essential the use of low-pressure machines. The low pressure mixing machines CMC 2TJ are designed using modern technologies adapting them to the needs of all types of user.

Key benefits

- Simplicity of use

- Reliability

- Flexibility

- Low maintenance

- Complete customization

Dosage of components

- Volumetric metering pumps with high precision double gear

- Inverter driven variable flow

- Digital pressure regulators sensing component dosing pressure

Storage and conditioning components

- Component tanks with external insulated cavities for recycling cooling liquid, capacity: 70 Lt

- Automatic temperature control components using electrical resistance and cooling liquid shut-off solenoid valve

- Visual level indicators on component tanks

- Signaling level indicators of component backup

- Line washing valves and component tank discharge

Component mixing

- Self-cleaning head with independent valve component recycling

- Recycling and component casting pressures adjustable in head

- Dynamic mixer motor driven by pulleys and belt

- Calibration of the components directly from the mixing head

- Special head holder with joystick operated pneumatic cylinder

Machine control

- Touch screen for the control and display of the machine functions to guide the user through the choice of the programs to be set

- Machine cycles: CALIBRATION, MANUAL, WORK

- 100 mixing programs selectable from the keypad set on the mixing head

- Data management software: number of daily and total cast pieces; component partial and total consumption; chronological list of the alarms which occurred; graph of component casting pressures; maintenance reminders

OPTIONAL

- CMCCPI

Component flow controllers for the display of the total flow values, and of the single components and the testing of the mixing ratios

- CMCAC

Slow gate paddle agitator scraper on tank bottom to lift any decanted material or color

- CMCH2OE

Automatic environment friendly washing system of mixing chamber with hot water

- CMCLCC

Level of charge of anti-crystallization components

- CMCPRO

Diaphragm pumps for loading components complete with suction tube

- CMCGMPD

Magnetic coupling drive for metering pumps to eliminate completely component leaking due to seal wear

- CMCFRH

Refrigeration unit for component cooling automatically supplied by the machine so as to reduce wear and power consumption

- CMCSC

Shell and tube heat exchangers for conditioning of components

- CMCBS

Special head holder arm following customer request

- CMCMR

Remote monitor positioned on the control keypad

|

Depliant download (pdf 1,1Mb) |